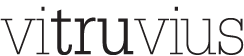

Projeto paramétrico do A2 cockpit [ONL]

Maycon Sedrez: Hi Pieter, my first question would be: have you used recursion or a generative system in the design process?

Pieter Schreurs: Well, that depends on how you approach generative design, on how you look at that. I mean, a lot of our designs are based on, let’s say, swarming technology, where you have individual nodes in space that define the position of the architectural elements on the overall shapes or building bodies. They are part of a unified system and inform each other about their relative position and the structural system and cladding system are generated based on these nodes. The point cloud forms the base of the architectural design in that sense, and everything is generated on that. So, our designs are always build on a certain logic that creates an integrated system, with which we start making the shape or that defines the complete shape of the building, so all components are generated based on that same logic. We have several examples, and I think the prime example is the A2 cockpit in Utrecht along the A2 highway.

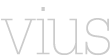

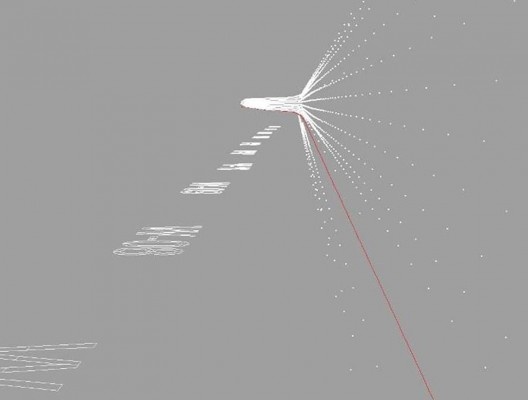

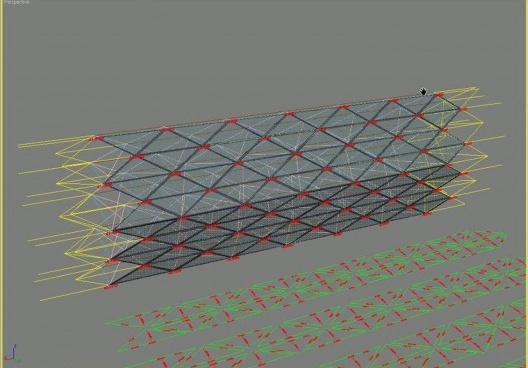

We designed an overall shape for the building body and on that shape we generated a point cloud, on which we generated the structural system and the cladding system that is fully integrated and completely load bearing. It’s not so much that we used a generative design approach for designing spaces or making spaces, but we use generative systems to create our structural systems and parametric details, which allows us to that and integrate design dynamically shaped complex building bodies, based on an integrated system with it´s own internal logics.

MS: So, is it also parametric? You can change the shape of the building in a parametric way?

PS: It is fully parametric. In our designs the starting point is always a parametric design process. So we always make a parametric system with which we start designing, in which we incorporate our design thinking and our logic. This allows us to always adapt to local circumstances and keep track of the consequences of our design decisions.

MS: So the complexity of the design is actually the result of this information that you use as input for the point cloud, or information that you get from the site.

PS: It’s not so much that our design is generative in that sense. We see ourselves as being designers, so we design a certain shape or building body. We use digital tools and scripting to inform our design and allow for a rich complexity and design freedom, while integrating all boundary conditions. We have, of course, thoughts and ideas on why and how things should work like they do. But we create a system that incorporates all these different types of information that accommodates for that type of design, for that shape. So, actually you could see it in such a way that we create a system that allows for a certain freedom for design from our own perspective. In our design approach we use the concept of powerlines, similar to car body design, to shape and streamline the building body, or a sound barrier, or a climbing wall, these different types of products and buildings.

MS: What software do you use?

PS: At the moment we use a lot of Rhino and Grasshopper. It is of course easy to use, easily accessible. We used a lot of different tools during the time that office exists. We used Python scripting as well. It really depends on the specific design and the requirements. We used Pro/Engineer and this kind of parametric engineering tools, because they are very accurate, the measures and geometry are very precise, which helps us controlling production geometry. But we have also used AutoCad for parametric design even, with AutoLISP routines to generate this kind of point clouds or logics and generate all different elements for the production. We also used tools like processing or sometimes also .net coding, like C# or Java to really making our own proprietary software to perform certain routines.

Nuvem de pontos para o projeto A2 Cockpit [ONL]

MS: It’s very computational design. Do you use physical models?

PS: Hardly. It’s very, very digital. We have a primarily digital way of working, I mean, of course we use sketching in the first phases of design. But we try to, as early as possible, start using the digital tools available and implementing and thinking about the complete integrated process. Also to be able to quantify and control the available parameters as early as possible. One of the key items in our design strategy is to integrate as much information, but also as many different actors or factors that influence the building process as early on in the process as possible. What we now, in our projects, are trying to do is to create a platform in which we are able to, in the very beginning, work together with, for example, the construction designers, the engineers, the climate designers. Working in a digital environment and incorporating all these different factors already in the very first phase of the design. Trying to understand what are the parametric relationships between these elements and then create sort of a model that you can start molding.

Quantificação das partes para o projeto A2 cockpit [ONL]